Why use an Electrostatic Sprayer?

Incorporating well-established technologies in innovative ways has become essential for facilities to adapt to the evolving standards of cleanliness in the post-pandemic era. The Environmental Protection Agency (EPA) has recently begun regulating these technologies in response to the pandemic, given the prevalence of misleading claims in the market. Navigating the multitude of options available and selecting the right device to suit specific facility and operator requirements can be a daunting task.

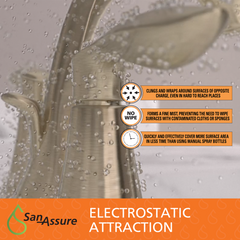

San-Assure has rigorously tested its sprayer to meet the latest EPA requirements. Electrostatic sprayers offer the advantage of disinfecting or sanitizing large areas significantly faster than traditional manual trigger spray and wipe methods. While these benefits are noteworthy, the absence of comprehensive government regulations in this field raises questions about how to determine the genuine capabilities of an electrostatic sprayer. Evaluating factors like device safety, functionality, ease of use, and real-world effectiveness becomes paramount in the assessment of electrostatic sprayers.

Selecting the Right Electrostatic Sprayer

When considering an electrostatic sprayer, key considerations should revolve around sprayer design, system safety, ease of use, and performance verification. When choosing disinfectants and sanitizers to use with the device, it's crucial to select products that are EPA-registered and explicitly state electrostatic spraying as an approved application method on their master label. Using a disinfectant or sanitizer in a manner not indicated on the EPA label is a violation of federal law.

System Safety

The choice of chemistry must be matched to specific sprayers to determine the required Personal Protective Equipment (PPE) for operators and to assess re-entry times for bystanders. Manufacturers like San-Assure who produce both devices and chemistries are best equipped to conduct safety assessments, as they can test them as a system. While disinfectants might be suitable for electrostatic sprayers, a thorough risk assessment is crucial since PPE requirements for electrostatic application may differ from traditional methods. Manufacturers should provide Safety Data Sheets (SDS) for each recommended disinfectant or sanitizer for use with the sprayer, indicating the appropriate PPE.

The type of chemistry used can also influence safety recommendations. Some formulas suitable for trigger sprayers may cause excessive odors or irritation when applied through an electrostatic sprayer. Ideal electrostatic sprayer disinfectants contain minimal ingredients and no fragrances. Each disinfectant must be tested with a specific electrostatic sprayer to ensure that the emitted product levels remain within established limits. San-Assure has performed this search for you to couple its sprayers with a disinfectant that has no odor, minimal ingredients, and no fragrances.

Facilities should also consider whether solutions are ready-to-use or require dilution before application. While dilutable products can be cost-effective, they add complexity, potential for human error, and increased safety risks if chemicals are mixed improperly.

Ease of Use

Operator experience is a critical consideration. Regardless of the chosen device and chemistry combination, manufacturers should offer training for personnel. Devices should also be ergonomically designed to ensure operator comfort throughout their shift.

System Performance

Evaluating whether an electrostatic sprayer fulfills its claims is essential. Both manufacturer testing and real-world assessments are significant in demonstrating system performance. Manufacturer testing includes efficacy testing, surface compatibility, object wrap demonstrations, cost-benefit analyses, and surface coverage rates. Real-world testing should encompass cost analyses, efficacy confirmation, compatibility with facility surfaces, and impact on relevant outcomes, such as infection rates. Frequent surface cleaning and disinfection are pivotal in eliminating environmental sources of infection transmission.

The EPA does has just begun to set standards for electrostatic sprayers themselves. It is vital to confirm that the sprayers have been tested with the disinfectant to make sure it meets with EPA guidelines. Only EPA-approved disinfectants or sanitizers with electrostatic spraying listed as an approved application method should be used. Additionally, the EPA now requires manufacturers to provide data demonstrating that their sprayers deliver the expected efficacy when used with the specified disinfectants and sanitizers.

The most rigorous way to confirm real-world efficacy is through surface swab testing, which quantifies the reduction in live microorganisms on surfaces before and after disinfection. ATP testing is useful for overall cleaning assessment but cannot verify the presence of live microorganisms. ATP testing should serve as a training tool for cleaning staff, not as a disinfection assessment method. Additionally, surface compatibility testing is crucial, as the chemical compatibility applied through an electrostatic sprayer can differ from other methods. Manufacturers should also demonstrate their sprayer's ability to effectively distribute disinfectants and sanitizers to all sides of complex objects.

Real-world evaluations of electrostatic sprayers provide practical confirmation of a product's claims. These results should be published in reputable journals or provided by the manufacturer in the form of a study summary. It is advisable to inquire if device manufacturers collaborate with reputable facilities to generate real-world evidence supporting their sprayer technology.

Electrostatic spray technology represents a comprehensive system rather than a stand-alone device. Therefore, when considering the purchase of an electrostatic sprayer, it is vital to assess the technology for its safety, trustworthiness, and proven effectiveness. A reliable system can help facilities demonstrate their commitment to providing a safe environment for both staff and occupants of treated spaces.

(Reference: "Evaluating Electrostatic Sprayers for Surface Disinfection" by Katherine Velez, Ph.D., Senior Scientist at Clorox Healthcare, FacilitiesManagement.com)

Navigation

Search

About

Technology

Resources

Professional Use

Contact

Newsletter

Accessibility

Terms of Service

Refund Policy

Privacy Policy

Warranty Registration

Contact us

About us

San-Assure provides multi-surface cleaning solutions that allow you to disinfect and sanitize every surface in your home. Our EPA-Registered sanitizer is safe to use and our electrostatic attraction technology provide full coverage disinfecting.

*simulated image.